More fun with Clevelands

by Graham ![]()

The brakes on my Long are standard Cleveland brakes, mated to 5 inch wheels. The braking system has used DoT 5 brake fluid since the plane first flew in 1995. The brakes are not as good as I would ideally like (you certainly cannot lock the wheels under braking_) but they are reasonably effective, and I have only once experienced brake fade - after landing downhill at Sedona several years ago, the brakes faded at the very end of the rollout (although I still comfortably made the last intersection of the runway).

I would like to replace the brakes with Grove brakes at some point, because the Groves have greater braking power, and also appear to be of a higher quality than the Clevelands, but this is a future project.

Based on my experience since I bought the plane, the life of caliper piston o-rings is no more than 5 years when using DoT 5. (see other postings about the Marco Island incident and the caliper piston incident to answer the question: how do I know this?). The o-rings were last replaced 4 years ago.

I finished working on the plane yesterday to fit the new intercom, and it was time to go for a test flight. My pre-flight checklist includes an item when I get in the plane to perform a brake pedal test (see a future "True Confessions" posting for why I do this).

When I sat in the plane and tested the brakes, both pedals felt spongy. This, at the very least, means that there is air in the system. The brakes on my plane do seem to accumulate small bubbles in the caliper area over time, especially if the plane is not flown for a while. I assumed that this was the issue, which would require a brake bleed.

I pulled the plane back into the hangar, and removed the wheelpants. It was immediately apparent that the caliper pistons were probably leaking - the accumulated brake dust around the caliper body was moist on both brakes. This dust should be dry and easily removable.

When I removed the calipers and brake pad assemblies, I found that both pistons were leaking past the o-rings ; the brake pads and backing plates were wet. Additionally, the right hand pads were worn down almost to the point where the rivet bases were flush with the pad surface, and the left hand pads were almost as worn. The Annual Condition Inspection is due up in June, but this was maintenance work that needed to be done before I could take to the air.

I replaced the o-rings in both caliper pistons, and replaced the brake pads. This does not take a lot of time once you have done it once or twice. I also found a new technique for bleeding the calipers after replacing the o-rings, which I believe to be as effective as a bottom-up brake bleed. (This technique will appear in a future Central States newsletter).

After 1 1/2 hours of unplanned work, I was able to get in the plane, press the brake pedals, and get a nice solid feeling from the brakes.

I bedded in the brakes by performing stops from a slow taxi, and then performing 3 sudden stops from fast taxi speed on the runway. I also performed a rapid stop on landing after my test flight. The brakes are now bedded in, and feel pretty effective (as effective as the standard Clevelands can be on this plane). Brake pads that are not bedded-in result in a "springy" brake pedal, where a lot of pedal force is required to achieve good braking.

The Intercom is fitted and The Plane Flew!

by Graham ![]()

Well, after nearly 6 months of down-time, N131JF returned to the skies just after 7.00pm last night.

I received the repaired intercom from Spruce just over a week ago. A quick test by plugging it into the wiring harness proved that it worked!

That was the easy part. The more intricate part was completing the installation and buttoning everything up in the plane. That took some time, with some more help from Jesse.

There were several little things that needed to be fixed/optimized along the way. One issue was that several wires in the intercom harness had been inadvertently routed across wires running down to the rear of the plane. This made it impossible to cable-tie the latter set of wires in their original position, so we had to re-route several wires (cutting and re-joining a couple of them along the way).

All of the wiring bundles had to be re-tied throughout the plane. Additionally we were able to further reduce the height of the wiring bundle leading to the Molex harness connector on the intercom. This allowed us to fit the top of the intercom case to the bottom half of the case (although we did need to enlarge the hole through which the wiring harness enters the side of the case). This improves shielding and protection, and also ensures that the Molex connector cannot come away from the intercom, since the wiring harness and Molex connector is being pressed down in place by the top of the intercom casing.

I finally took to the skies just after 7.00 pm (see most recent posting for other information). The intercom works, but it requires some adjustment using the onboard pots. The main issue is that the noise reduction threshold is set too high, so the noise reduction is not currently kicking in. I will fix this prior to the next flight, probably by running a ground test with the engine running.

The Intercom saga - latest

by Graham ![]()

Returned to Spruce, Spruce sent to FlightTech who fixed it, now back on its way to Spruce.

One day I will get an intercom...

KS Avionics join the Great Suppliers List

by Graham ![]()

Several months ago, my #2 EGT probe finally failed. It had been showing signs of failure for some time - the reading for the probe would appear and disappear in flight. I found that the stainless steel clamp holding the probe in place was partially broken, which had caused the probe to come loose. Tightening the clamp and fixing it in place with safety wire did not cause the probe to work again.

Since the probe was over 19 years old, and a switch to #4 cylinder showed that it was the probe that had failed, not the wiring, I ordered a replacement from KS Avionics. This duly arrived, and I went to fit it. When I removed the old clamp and the probe, the probe fell apart in my hands. I sent it back to KS Avionics with a note to the effect that "I guess it just went to the EGT probe home in the sky". They wanted me to send it back so that they could examine it and determine the cause of failure.

Today I received the sort of letter that I love to get. It was a handwritten note from KS Avionics explaining the cause of the failure. Plus a check for $25.00 as a credit against the replacement probe.

What a fine bunch of people KS Avionics are. They stand behind their product and provide exemplary service.

Intercom saga continues

by Graham ![]()

The intercom box, sent back from Illinois by FlightTech, finally arrived back in Irving on Wednesday. Because I have been as sick as a dog since last Sunday, I finally got around to opening it up on Thursday.

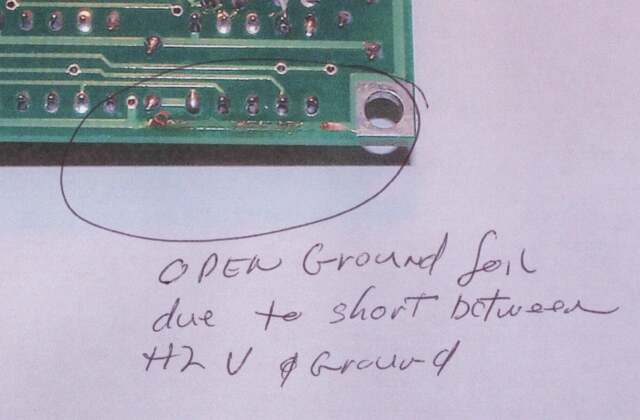

The most interesting revelation from the report that FlightTech wrote (written as a dummy invoice) was that the damage to the circuit board was on the underside of the board. We could not have been responsible for the damage, since we never needed to remove the board from the base of the box that contains it. The installation into the electrical area of the Long-EZ involves us simply plugging the 24-pin Molex connector into the top of the PC board, putting the top on the aluminum case, and fixing the case to the electrical components cover. The aluminum box and intercom unit spent its entire life until final plug-in sitting on a workbench away from the plane while Jesse rewired the existing intercom and radio circuits to take the new intercom, fitting the necessary Molex connectors to the wires (and hats off to him for doing this, because the pins in this Molex connector are incredibly small).

I talked to Aircraft Spruce on Thursday evening and explained the issue to them. They were surprised that FlightTech did not simply send me a replacement, but as I pointed out to them, FlightTech's verbal opinion to me on the phone was that this board had been returned from the field to Spruce, and had somehow found its way back out as an OK unit to me, when it was antything but OK.

Spruce sent me a return-paid USP package label, so the unit is going back to Spruce on Monday. We will then see what transpires.

Here is the photo of the damage to the board, annotated by FlightTech:

05/30/06 12:10:52 pm,

05/30/06 12:10:52 pm,